Bugatti's track-only hypercar, the Bolide, is nearing the end of its gestation, and Bugatti has taken a moment to highlight the car's safety, specifically the passive safety delivered by a carbon-fiber monocoque.

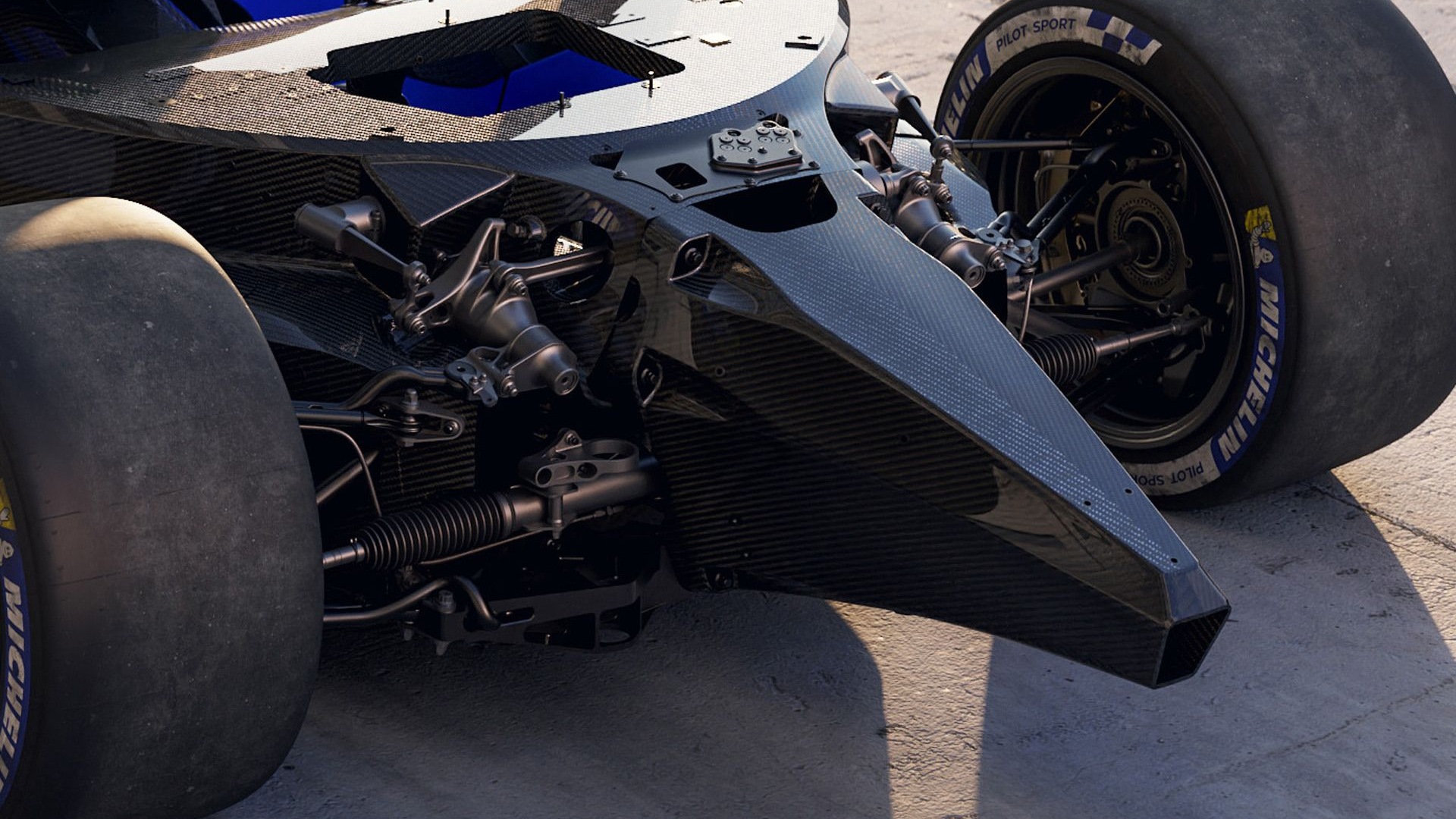

Just like a Formula 1 race car and many high-end performance cars for the road, the Bolide features a passenger cell known as a monocoque or tub, which integrates the roll cage and features subframes front and rear.

It's made from the same type of carbon fiber used in motorsports and meets the same regulations outlined by the FIA for top-level sports prototypes such as LMH and LMDh, according to Bugatti.

The monocoque is unique to the Bolide, with Bugatti's quad-turbocharged 8.0-liter W-16 engine positioned approximately 2.3 inches closer to the center of the vehicle than in the Chiron. The decision to create a unique monocoque was not only due to the level of track performance Bugatti is targeting for the Bolide but also to meet crash safety requirements for race cars, which are different from the world of road cars. Bugatti said a clean-sheet design meant zero compromises.

Bugatti Bolide rolling chassis

Examples of the crash safety requirements include rollover tests. One of the most demanding is a test that applies a load of more than 16,500 pounds to the A-pillar. To pass the test, the maximum deflection must be less than two inches at the point where the load is applied, and no failure of the structure is allowed. Another rollover test applies almost 26,500 pounds to the B-pillar, while a third major test involves a longitudinal load of approximately 13,200 pounds to simulate a rollover resulting in a rear impact with a barrier.

Key to passing the tests include having the right layout and thickness for the monocoque walls, as well as the material used.

“Since we made the decision to turn the [Bolide concept] into reality, we knew we were going to be uncompromisingly focused on several important design and development areas, but that focus was especially honed in high-performance and safety on-track attributes,” Christian Willmann, Bugatti's chief engineer for the Bolide, said in a statement.

Remarkably, the production version of the Bolide looks very close to the concept that was unveiled in 2020—and never actually intended for production. Differences from the concept include a more pronounced roof scoop, fewer fins behind the front wheel arches, the addition of side mirrors, and a revised rear wing with an adjustable component. The decision to go with actual side mirrors instead of a more aerodynamically efficient camera system is because mirrors allow drivers to estimate distances to other cars more quickly, Bugatti said.

Bugatti Bolide prototype

Bugatti Bolide prototype

Bugatti Bolide prototype

Other safety features include a fire suppression system, six-point harnesses, HANS head and neck safety system, and headrests that mount to the door frames to form a structural component. The headrest brackets, made from 3D-printed aluminum, weigh just over half a pound but can withstand a load of more than 1,500 pounds. The Bolide also comes with active safety features such as traction control, electronic stability control, and an anti-lock braking system.

The car's W-16 engine is tuned to deliver 1,578 hp on 98-octane fuel. However, it can also run on 110-octane racing fuel, which ups the output to 1,824 hp. As the car is designed for track use, all four turbochargers are always in operation. The engine has also been tuned to rev higher than in road-going Bugattis, and is mated to an upgraded version of the 7-speed dual-clutch automatic found in the road cars.

The dry weight for the Bolide is a little under 3,200 pounds, and performance should be on par with top motorsport levels, according to Bugatti.

Bugatti will build a total 40 examples and all build slots are gone, despite the a price of 4 million euros (approximately $4.3 million at current exchange rates). Deliveries start in 2024.