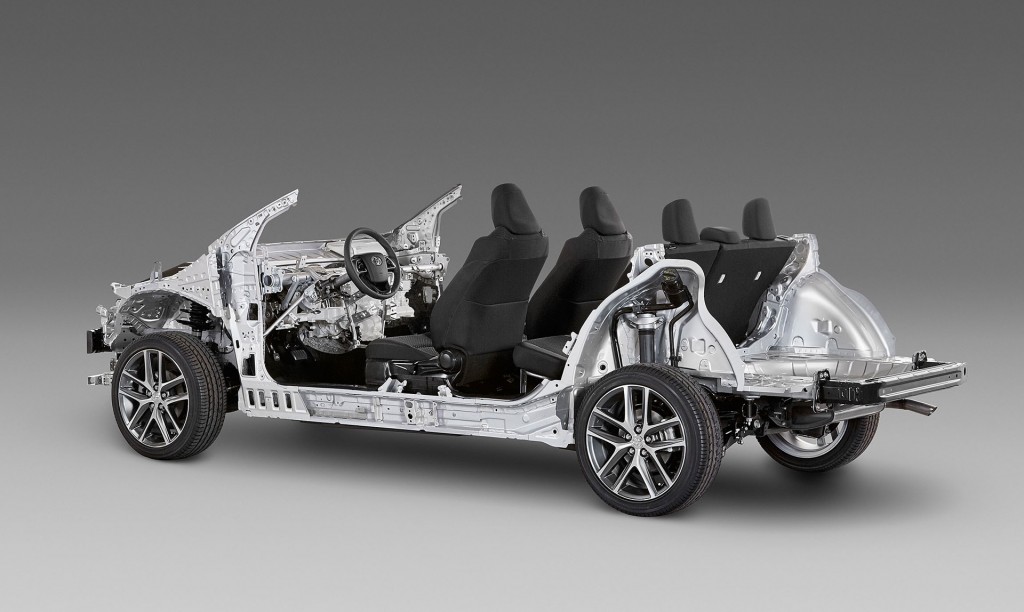

Toyota is implementing a raft of measures to ensure it remains among the top automakers not only in terms of volume but profitability, too. And one of the key measures is the introduction of a new modular platform, the Toyota New Global Architecture (TNGA), designed for mid-size cars. Other measures include the launch of vehicles in new segments as well as a major overhaul of production methods.

ALSO SEE: Video Shows Just How Distracted Teen Drivers Can Get

The use of highly flexible, modular platforms in the auto industry is a proven means of speeding up development and reducing costs, substantially. Toyota already uses modular platforms but is taking things a step further with the TNGA, particularly in the area of strategic sharing of parts and powertrain elements. The automaker aims to reduce the call on its resources by 20 percent or more with the TNGA platform.

But it’s not just about cost savings. There will be performance and efficiency gains, too. In designing the platform, engineers have repositioned and lowered the center of gravity of powertrain components. They’ve also focused on reducing the weight of the size of certain components, while at the same time increasing overall body rigidity by as much as 30-65 percent thanks to higher strength materials and new laser welding techniques.

The powertrains, too, will be completely new. The automaker says it’s increased the overall fuel efficiency of its powertrains by about 25 percent and overall power output by more than 15 percent, gains achieved by improving the thermal efficiency of its engines and reducing the parasitic losses of its transmissions. Its hybrid systems, meanwhile, are also being improved: Toyota is targeting a 15 percent rise in fuel efficiency thanks to a re-think of the drive unit layout and the design of smaller electric motors, inverters and batteries.

DON'T MISS: Mercedes-Benz Planning Pickup?

Toyota New Global Architecture (TNGA) modular platform

The first of Toyota’s new TNGA-based vehicles will appear as early as this year, most likely starting with the next-generation Prius. Separate platforms will be developed for Toyota’s compact cars and large, front-wheel-drive models. A new platform for Toyota’s rear-wheel-drive models, most of them sold by Lexus, will also be developed. Toyota expects that by as early as 2020, half the vehicles it sells worldwide will use the new platforms.

In addition to the way it develops its cars, Toyota will also change the way it builds them. The automaker put a freeze on new production plant projects back in 2013 in order to focus on improving efficiencies at current sites, and as a result it has increased its total line utilization rate from around 70 per cent in 2009 to more than 90 percent today.

READ: Why Volvo Is Going Touch-Screen, But Skipping Capacitive Tech Entirely

Toyota is also working on reducing the cost required to start production of an all-new model. The automaker is aiming to cut the amount of capital investment needed to ready a production line for a new model by about half, compared to 2008 levels. This work also covers the production of new engines, transmissions and related components.

Through these combined projects, Toyota aims to run plants that are always competitive, rather than relying on volume to achieve results.