Grouped under its range of new SKYACTIV fuel saving technologies and co-developed with Sumitomo Metal Industries, the new steel is not only much stronger than regular steel, it’s also significantly lighter.

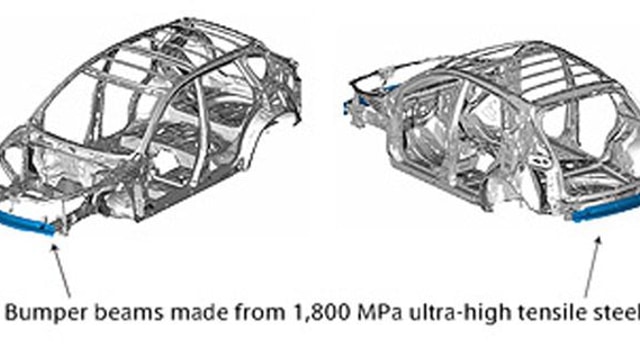

Mazda will use the ultra-high tensile steel to fabricate bumper beams, which fit inside the front and rear bumpers and mitigate damage in the event of a collision.

The bumper bars are 20 percent stronger and 10.5 pounds lighter than previous versions and are a key part of Mazda's next-generation, lightweight and highly rigid vehicle bodies. They will work in conjunction with a new energy absorbing structure as well as an expanded use of high tensile steel in other areas of the vehicle body.

Mazda ultra-high tensile steel

Safety and fuel economy gains aren’t the only benefits, however. Reducing the weight of bumper beams is particularly important because, as they are incorporated into the body structure at the farthest point from the vehicle's center of gravity, their weight has a considerable effect on dynamic performance and responsiveness.

Beyond the CX-5, expect the greater use of ultra-high tensile steel in most new Mazdas going forward.

For full details on the 2012 Mazda CX-5, click here.