As enthusiasts, we've all decried the incessant bulking-up of our favorite vehicles over the years. Adding the necessary safety and emissions equipment to meet regulatory requirements has led to a massive increase in the average weight of most cars over the past 30 years. But a new aluminum and foam sandwich material may help solve the problem.

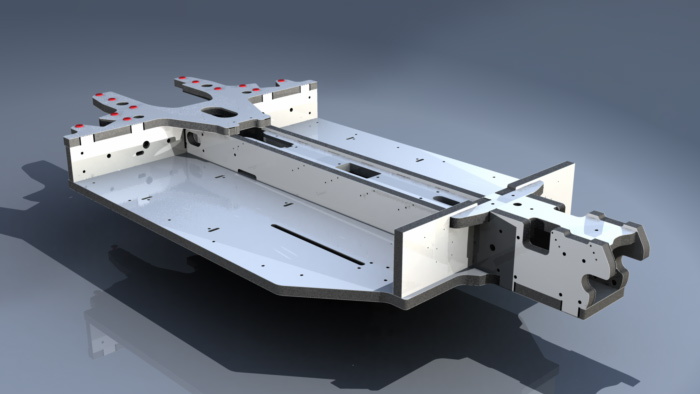

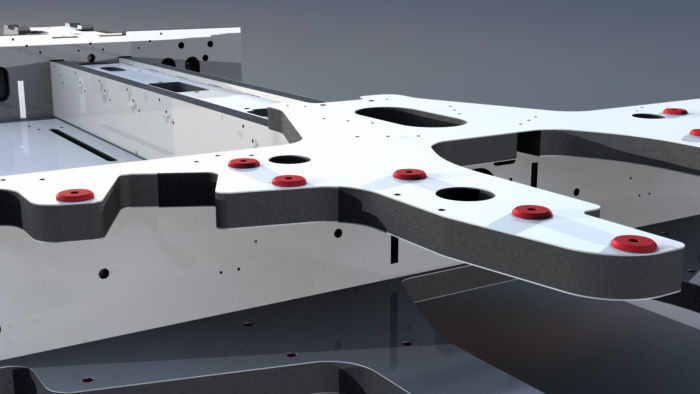

Consisting of ARPRO, a propylene-based foam, sandwiched between two thin sheets of aluminum, the material is light yet also strong due to its three-ply construction. It's also cheaper than carbon fiber and can be completely recycled. Sounds like the perfect material, right?

It may be, though a sandwich construction will no doubt mean what would have been minor fender benders in a steel-chassis car end up requiring complete replacement of a subframe, as it won't likely be easily repairable.

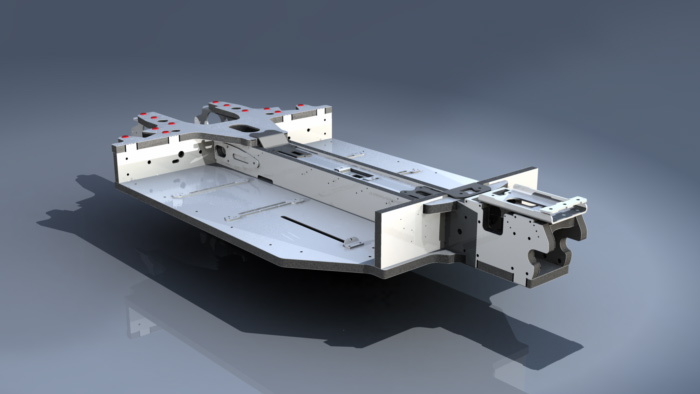

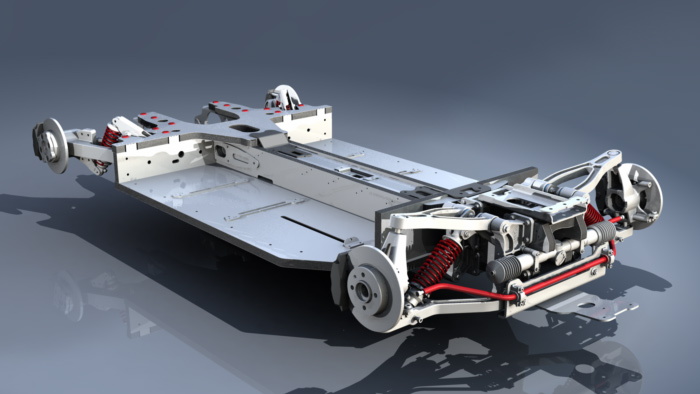

The company behind the product, Inrekor, says use of the material could cut a car's weight by up to 30 percent. That's a significant amount of poundage--around 1,000 pounds off the average family sedan, and between 700-900 pounds off even a relatively lightweight sports car, though the gains there are likely to be smaller given existing weight-savings measures already employed.

Those of you with an eye for the obscure may be thinking, "hey, Corvettes already use a similar weight-savings approach by using balsa wood sandwiched between carbon fiber sheets in some parts of the car," and you're right. The Inrekor solution would be cheaper and (presumably) easier to mass-produce, however, relying on stamped aluminum rather than vacuum-formed or molded carbon fiber. Also, the Inrekor solution is intended more as a substitute for heavy steel structural elements rather than a body/sheetmetal replacement.

Pairing the new material's weight savings with cost savings means a new breed of lighter, cheaper sports and supercars could eventually find their way to market. That's a combination of features we can all support. We won't be holding our breath, though, as it will likely be two years before a proof-of-concept car is produced, and another 2-5 years before anything retail is built with the material given product cycles and manufacturer tooling and durability testing.