Ford has invested more than $55 million for tooling and equipment upgrades at the Ohio plant, and approximately 250 employees are needed for each shift. To ensure top level quality and reliability, a new database system attaches a sophisticated “birth history” to each engine, which allows plant engineers to track every stage of production.

The engine history, maintained in a microchip database, will include hundreds of metrics and allows engineers to trace the precise path taken by any part so any quality control issue can be traced back to its source.

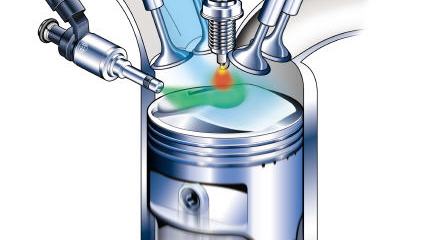

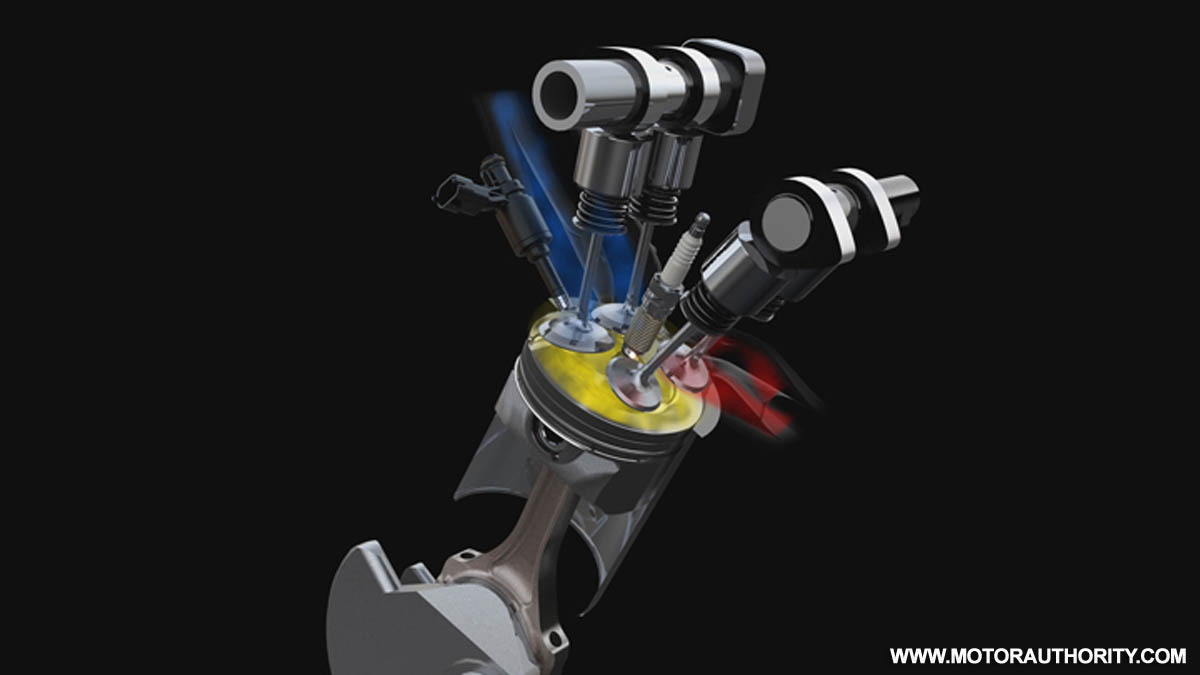

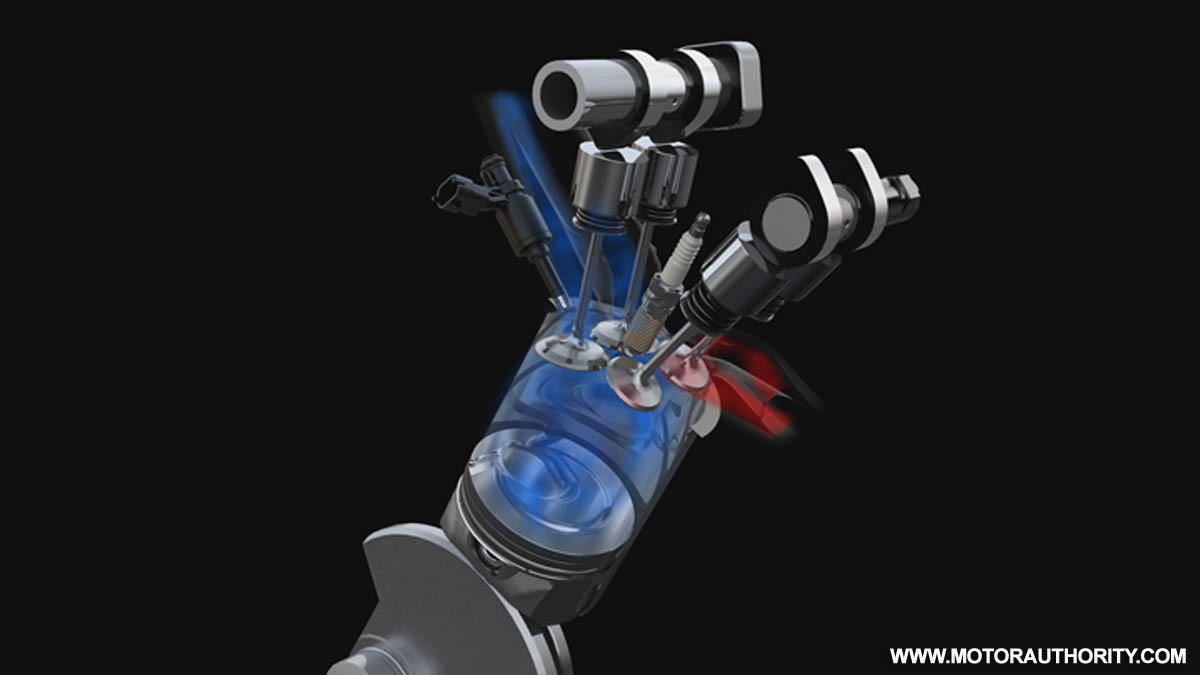

The first EcoBoost engine is a 3.5L V6 unit with 355hp (265kW) at 5,700rpm and 350ft-lb (474Nm) of torque from 3,500rpm. Thanks to a combination of direct-injection and turbocharging technologies, a 10-15% fuel-economy benefit is expected versus normally aspirated V8 engines found in the same class as the Ford vehicles equipped with an EcoBoost engine.

The V6 unit is the first in a wave of EcoBoost engines coming from Ford as part of a strategy to bring affordable fuel efficiency to millions, with more than 90% of the company’s North American lineup to be fitted with EcoBoost technology by 2013.